Nylon 6, also known as Polyamide 6 (PA 6), is one of the most widely used engineering thermoplastics in modern industrial design. Its popularity is not accidental. Engineers and manufacturers consistently choose Nylon 6 for components that operate under continuous motion, heavy loads, and repeated friction because it delivers a rare balance of durability, efficiency, and reliability. In many mechanical systems, friction is unavoidable, but material choice determines whether that friction becomes a long-term problem or a manageable design factor.

Unlike conventional plastics that degrade quickly under stress, Nylon 6 maintains structural integrity even when exposed to constant movement and pressure. In fact, in several friction-heavy applications, it competes directly with metals by offering lower wear, reduced noise, and lighter weight. These advantages make it especially valuable in industries where performance consistency, reduced maintenance, and operational efficiency are critical.

- Understanding Friction-Heavy Mechanical Systems

- Strong Wear Resistance

- Low Friction Surface Properties

- Impressive Thermal Stability Under Friction

- High Impact Strength and Toughness

- Load-Bearing Capability in Moving Parts

- Resistance to Fatigue and Repeated Motion

- Lightweight Advantage Over Metals

- Chemical and Environmental Resistance

- Conclusion

- Frequently Asked Questions

Understanding Friction-Heavy Mechanical Systems

Friction-heavy mechanical systems are environments where parts remain in constant contact while moving against one another. Examples include conveyor guides, wear strips, gears, bushes, bearings, and sliding rails. In such systems, materials must resist abrasion while still allowing smooth motion. If friction is not properly managed, it can lead to heat buildup, deformation, surface damage, and early component failure.

Traditional materials such as steel and aluminum handle load well but often suffer from high friction, noise, and the need for lubrication. Standard plastics, on the other hand, may offer lower friction but fail under sustained stress. Nylon 6 bridges this gap by providing a surface that slides smoothly while maintaining the strength needed to withstand mechanical demands over long operating cycles.

Strong Wear Resistance

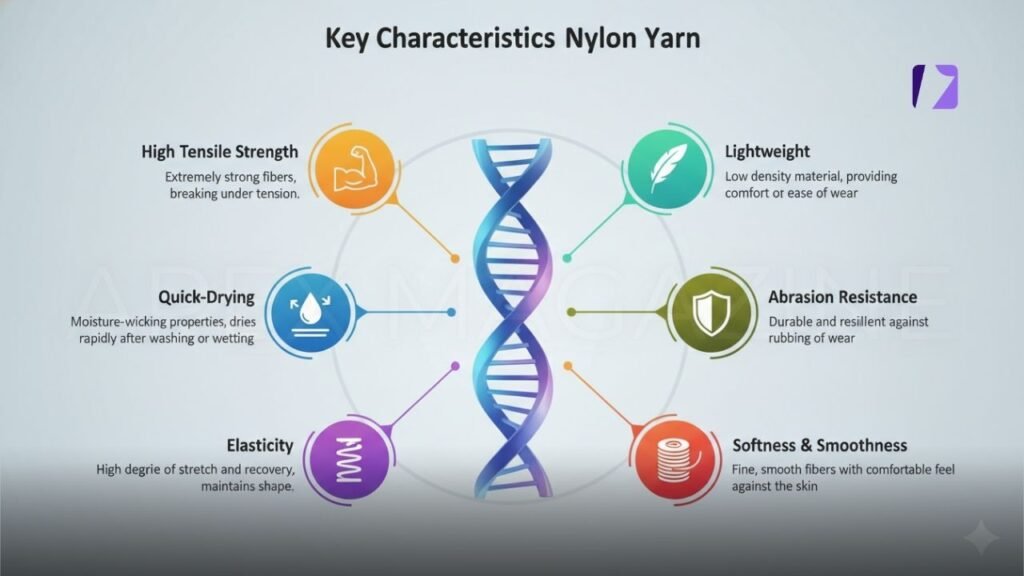

One of the most important reasons Nylon 6 performs so well in friction-heavy setups is its exceptional wear resistance. The material is engineered to withstand constant rubbing without losing its shape or surface quality. Even when exposed to repeated sliding contact, Nylon 6 resists abrasion far better than many common thermoplastics.

When you use a Nylon 6 extruded sheet or machined component, you benefit from a surface that remains smooth over extended periods. This durability reduces the frequency of part replacement, which directly lowers maintenance costs and minimizes system downtime. In high-usage environments, this consistency is critical for uninterrupted performance.

The wear resistance of Nylon 6 also supports precise movement in mechanical assemblies. Components such as guide rails and wear pads maintain dimensional stability, allowing machinery to operate accurately even after long-term use. This reliability makes Nylon 6 ideal for automated systems where tolerance control is essential.

Low Friction Surface Properties

Nylon 6 naturally exhibits a low coefficient of friction, which allows moving parts to glide rather than grind. This property is especially valuable in systems where smooth motion is required to prevent sudden jerks or uneven movement. Reduced friction improves operational stability and protects connected components from unnecessary stress.

A smoother sliding action also leads to quieter operation. In machinery where noise control matters, such as packaging lines or indoor industrial equipment, Nylon 6 helps reduce vibration and sound generated by friction. Over time, this contributes to a more controlled and predictable mechanical environment.

Another advantage of low friction is reduced reliance on external lubrication. While lubrication may still be used in some designs, Nylon 6 can often perform efficiently without constant oil or grease application. This simplifies maintenance routines and keeps systems cleaner, especially in environments where contamination must be avoided.

Impressive Thermal Stability Under Friction

Friction-heavy systems naturally generate heat, especially during long operational cycles. Many plastics soften or deform under elevated temperatures, leading to loss of alignment and reduced performance. Nylon 6, however, demonstrates strong thermal stability that allows it to maintain its shape and mechanical properties as temperatures rise.

This stability ensures that components such as spacers, wear strips, and bushes remain dimensionally accurate even after repeated heating and cooling cycles. Nylon 6 does not warp easily, which is essential for maintaining smooth motion paths and consistent contact surfaces.

Thermal resilience also extends the lifespan of components. By resisting heat-related degradation, Nylon 6 supports long-term use in demanding environments where friction-induced heat is unavoidable. This makes it a dependable choice for continuous-duty machinery.

High Impact Strength and Toughness

In addition to managing friction, many mechanical systems experience sudden loads or impacts during operation. Nylon 6 offers high impact strength, allowing it to absorb shocks without cracking or breaking. This toughness provides an added layer of protection in dynamic systems where components may collide or shift under pressure.

The material’s ability to handle repeated impact is particularly useful in automated and high-speed machinery. Nylon 6 does not become brittle under stress, which helps maintain performance consistency throughout extended operating periods.

Its natural flexibility complements its strength, enabling parts to return to their original shape after impact. This balance between rigidity and resilience reduces the risk of sudden failure and supports safer system operation.

Load-Bearing Capability in Moving Parts

Despite being a thermoplastic, Nylon 6 performs exceptionally well under mechanical load. It can support significant weight while still allowing smooth movement, which is essential in friction-heavy applications. This load-bearing ability makes it suitable for gears, rollers, and structural sliding components.

Under continuous pressure, Nylon 6 distributes stress evenly across its surface. This reduces localized wear and helps maintain uniform contact between moving parts. As a result, systems experience fewer performance inconsistencies over time.

The combination of strength and flexibility also prevents permanent deformation. Nylon 6 components retain their original dimensions, ensuring reliable performance even in systems that operate under constant load.

Resistance to Fatigue and Repeated Motion

Mechanical fatigue is a common issue in systems with continuous movement. Materials that cannot handle repeated stress eventually crack or fail. Nylon 6 resists fatigue effectively, allowing it to perform reliably through countless motion cycles.

This fatigue resistance is particularly valuable in applications such as conveyor systems and automated production lines. Nylon 6 components maintain functionality even after extended use, reducing the risk of unexpected breakdowns.

By resisting fatigue-related wear, Nylon 6 helps manufacturers achieve longer service intervals and improved system reliability. This contributes to overall operational efficiency and cost savings.

Lightweight Advantage Over Metals

Another key benefit of Nylon 6 is its lightweight nature compared to metals. Reducing component weight lowers the overall load on mechanical systems, which can improve efficiency and reduce energy consumption.

Lighter components also make installation and replacement easier. Maintenance teams can handle Nylon 6 parts with less effort, speeding up repair processes and reducing labor strain.

Despite its lighter weight, Nylon 6 does not compromise on strength or durability. This makes it an attractive alternative to metal in many friction-heavy applications where efficiency and ease of handling matter.

Chemical and Environmental Resistance

Nylon 6 also performs well in environments exposed to oils, fuels, and industrial chemicals. Its resistance to many substances helps preserve surface integrity and mechanical properties over time.

This chemical stability ensures that friction-heavy components do not degrade prematurely due to environmental exposure. In industrial settings, this reliability supports long-term system performance and safety.

The material also adapts well to varying humidity and operating conditions, further enhancing its versatility across different industries.

Conclusion

Nylon 6 stands out as a highly dependable material for friction-heavy mechanical systems due to its unique combination of wear resistance, low friction, thermal stability, and impact strength. These properties allow components to operate smoothly, efficiently, and reliably even under continuous motion and heavy load.

By choosing Nylon 6, engineers and manufacturers gain a material that reduces maintenance demands, extends component lifespan, and improves overall system performance. Its ability to outperform many traditional plastics and even rival metals in specific applications makes Nylon 6 a practical and forward-thinking solution for demanding mechanical designs.

Frequently Asked Questions

What makes Nylon 6 suitable for friction-heavy applications?

Nylon 6 performs well in friction-heavy environments because it combines low friction, high wear resistance, and strong mechanical strength. Its surface allows smooth sliding contact, which reduces abrasion between moving parts. This balance helps components last longer while maintaining consistent performance under continuous motion.

How does Nylon 6 compare to metal in high-friction systems?

In many sliding and wear applications, Nylon 6 can outperform metal by reducing friction, noise, and lubrication needs. Unlike metal, it does not gall or seize easily and produces less heat during movement. Its lightweight nature also lowers overall system load, improving efficiency.

Can Nylon 6 handle high temperatures caused by friction?

Yes, Nylon 6 shows good thermal stability in friction-intensive systems. It maintains its shape and mechanical properties across repeated heating and cooling cycles. This stability helps prevent deformation, ensuring accurate alignment and reliable operation over long periods.

Is Nylon 6 resistant to impact and repeated stress?

Nylon 6 has high impact strength and good fatigue resistance. It absorbs shocks without cracking and performs well under repeated loading. This makes it ideal for parts such as gears, bushings, wear strips, and sliding pads that face constant stress.

VISIT MORE: APEX MAGAZINE