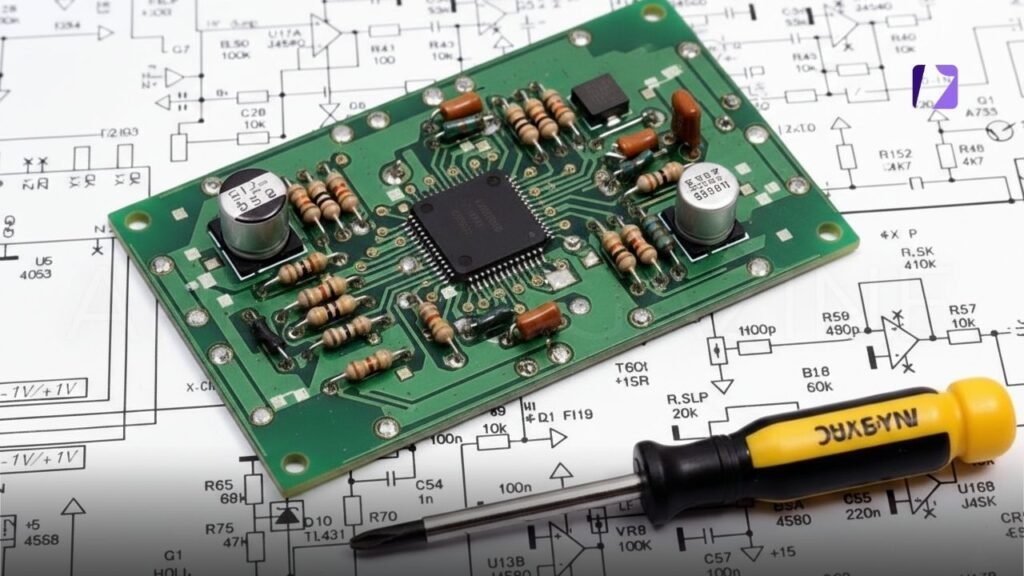

Behind every modern electronic device from advanced medical systems and mining control units to industrial automation panels and smart home products there is at least one printed circuit board (PCB) performing critical internal operations. While it may remain invisible to the end user, the Printed Circuit Board (PCB) is the foundation of functionality, stability, and performance.

In Australia, demand for high-quality PCB assembly services is growing rapidly. As local companies design increasingly complex electronic products, they require manufacturing partners who can deliver not only technical accuracy but also consistency, traceability, and compliance. Understanding how PCB assembly works and what separates average providers from reliable long-term partners can significantly reduce the risk of costly delays, rework, and field failures.

- What PCB Assembly Actually Involves

- Why Precision Matters in PCB Assembly

- The Australian Context: Standards, Compliance and Support

- From Prototype to Production: Designing with Assembly in Mind

- Choosing the Right Partner for PCB Assembly Services

- Balancing Cost, Quality, and Speed

- Preparing Your PCB Project for Success

- Conclusion

- Frequently Asked Questions

What PCB Assembly Actually Involves

PCB assembly (PCBA) is far more than simply placing components onto a board. It is a tightly controlled, multi-stage manufacturing process that transforms a bare PCB into a fully operational electronic module.

The process typically begins with component sourcing and kitting. This stage ensures that all required parts resistors, capacitors, integrated circuits (ICs), connectors, and specialised components are sourced from reliable suppliers and verified against the Bill of Materials (BOM). Component authenticity and correct specification are critical at this stage to prevent performance or compliance issues later.

Next comes solder paste printing. A precisely manufactured stencil deposits controlled amounts of solder paste onto each pad of the PCB. This step demands extreme accuracy. Even slight variations in paste volume can affect joint integrity during soldering.

The pick-and-place stage follows. Automated machines position surface-mount components onto the board using design data from CAD files. Modern machines can place thousands of components per hour, but accuracy must be measured in fractions of a millimetre.

After placement, boards move into soldering processes:

- Reflow soldering for surface-mount components

- Wave soldering or selective soldering for through-hole components

Temperature profiling during reflow is especially critical. Incorrect thermal curves can damage components, create weak joints, or cause solder defects such as bridging or voiding.

Finally, inspection and testing ensure reliability. These may include:

- Automated Optical Inspection (AOI)

- X-ray inspection for hidden joints

- In-circuit testing

- Functional testing under operating conditions

Each stage has tight tolerances. Small errors such as misalignment, insufficient solder, or poor temperature control can result in intermittent faults that only appear after deployment.

Why Precision Matters in PCB Assembly

At the scale of fine-pitch components and micro pads, “almost correct” is not acceptable. Precision directly influences electrical integrity, mechanical durability, and product lifespan.

Electrical Performance

Poor solder joints increase resistance, introduce electrical noise, and create unstable signal behaviour. In high-speed or sensitive circuits, these imperfections can compromise overall system reliability.

Mechanical Reliability

Many Australian industries including mining, defence, transportation, and energy operate in harsh environments. Vibration, temperature cycling, and moisture can expose weak solder joints quickly. Strong, uniform assembly is essential for durability.

Long-Term Longevity

Clean assembly processes reduce risks such as corrosion, solder whiskers, and contamination. Over time, these factors significantly influence product lifespan and warranty rates.

For companies serving regulated industries like medical or defence, reliability is not optional. It impacts compliance certifications, brand reputation, and liability exposure.

The Australian Context: Standards, Compliance and Support

Working with a local partner for custom pcb australia brings some specific advantages.

First, there is alignment with regional and international standards, from RoHS and REACH through to ISO-based quality systems and industry-specific requirements. Local assemblers are used to dealing with Australian safety regulations, certification pathways and documentation expectations, which reduces friction later in your project.

Second, you gain access to local technical support. Time zone alignment, the ability to visit the facility, and faster feedback loops all make debugging, design for manufacture (DFM) conversations and engineering changes smoother. Instead of waiting days for clarification, you can often resolve issues in hours.

Third, logistics become more predictable. Shipping within Australia reduces lead times and the risk of delays at customs, which is especially important for prototypes, urgent runs or maintenance batches.

From Prototype to Production: Designing with Assembly in Mind

The best PCB assemblies start with designs that respect manufacturing realities. This is where early collaboration between your engineering team and your assembler pays off.

Good DFM practice includes consistent pad sizing, sensible spacing around fine-pitch components, clear polarity and orientation markings, and panelisation decisions that suit the assembly line. It’s also worth considering which components are truly essential to keep in exotic packages and which can be swapped for more assembly-friendly equivalents without changing performance.

When your assembler is involved early, they can flag potential yield issues before you commit to a layout. That reduces the risk of repeated board spins and helps you move from prototype to small batch and then volume production with fewer surprises.

Choosing the Right Partner for PCB Assembly Services

With so much riding on the quality of your boards, selecting a partner for pcb assembly services deserves careful attention. Look closely at their process control: do they document and monitor each stage, from stencil cleaning to oven profiling? Ask about inspection methods AOI, X-ray, in-circuit or functional testing and how they handle non-conformances. Check whether they offer clear traceability from batch to component lot, which is vital if you ever need to investigate a field issue.

Inspection Capabilities

Reliable assemblers invest in:

- AOI systems

- X-ray inspection

- Functional testing environments

The depth of inspection reflects their commitment to quality.

Equally important is communication. A responsive partner will share DFM recommendations, highlight supply chain risks for specific components, and be transparent about lead times and capacity. Whether you’re working with a specialist like Precision Electronics or another Australian assembler, you want a team that behaves as an extension of your own engineering department, not just a black-box supplier

- DFM recommendations

- Supply chain risks

- Component obsolescence warnings

- Realistic production timelines

Balancing Cost, Quality, and Speed

Cost is always a consideration, but focusing on unit price alone can be misleading. Cheaper assembly that leads to higher failure rates, more rework or warranty claims quickly becomes more expensive overall.

A more useful lens is total lifecycle value: how much engineering time you save, how many boards pass first-time testing, how often you need to reschedule production, and how your end customers experience your product in the field. Australian assemblers that invest in modern equipment, skilled operators and robust quality systems may not be the cheapest per board, but they often deliver the best value over the life of a project.

Speed also matters, especially in competitive markets where being first with a stable product is a real edge. Local assembly, clear communication and a partner who understands your priorities can help you hit launch windows without cutting corners.

Preparing Your PCB Project for Success

Before you send off your next design, it’s worth taking a moment to set the project up properly. Clean, up-to-date BOMs, well-annotated Gerbers and pick-and-place files, clear test requirements and honest forecasts for future volumes all help your assembler plan effectively.

Ensure:

- BOMs are clean and current

- Gerber files are properly annotated

- Pick-and-place data is accurate

- Test requirements are defined

- Forecast volumes are realistic

When you treat PCB assembly as a strategic partnership rather than a last-minute procurement task, you get better boards, fewer delays and more predictable performance. In an environment where electronics underpin everything from critical infrastructure to consumer devices, that combination of precision and reliability is exactly what keeps Australian products competitive at home and around the world.

Conclusion

PCB assembly is not a simple transactional service. It is a strategic partnership that influences product performance, regulatory compliance, and long-term brand credibility.

In Australia’s evolving electronics landscape, precision and reliability are competitive advantages. Companies that treat PCB assembly as a collaborative, quality-driven process rather than a last-minute procurement decision position themselves for stronger product launches, lower lifecycle costs, and sustained market success.

Frequently Asked Questions

What is PCB assembly?

PCB assembly is the process of placing and soldering electronic components onto a printed circuit board to make it fully functional.

How long does PCB assembly take?

Prototypes can take a few days. Full production runs may take several weeks, depending on complexity and parts availability.

Why is DFM important?

Design for Manufacture reduces errors, improves yield, and prevents costly board revisions.

What inspections are used?

Common methods include AOI, X-ray inspection, and functional testing to ensure quality and reliability.

Is local PCB assembly better?

Local assembly offers faster communication, shorter lead times, and better compliance support.

Which industries need high-precision PCB assembly?

Medical, defence, mining, automotive, energy, and telecom sectors rely heavily on precise PCB assembly.

VISIT MORE: APEX MAGAZINE